Heat Treatment Processes Provide Specific Properties for Industrial Customers

GREEN BAY, Wisconsin – Heat treating steel and iron is a general description for the specialized services offered by Metals Engineering, Inc. Manufacturers depend on these services to produce industry-leading products.

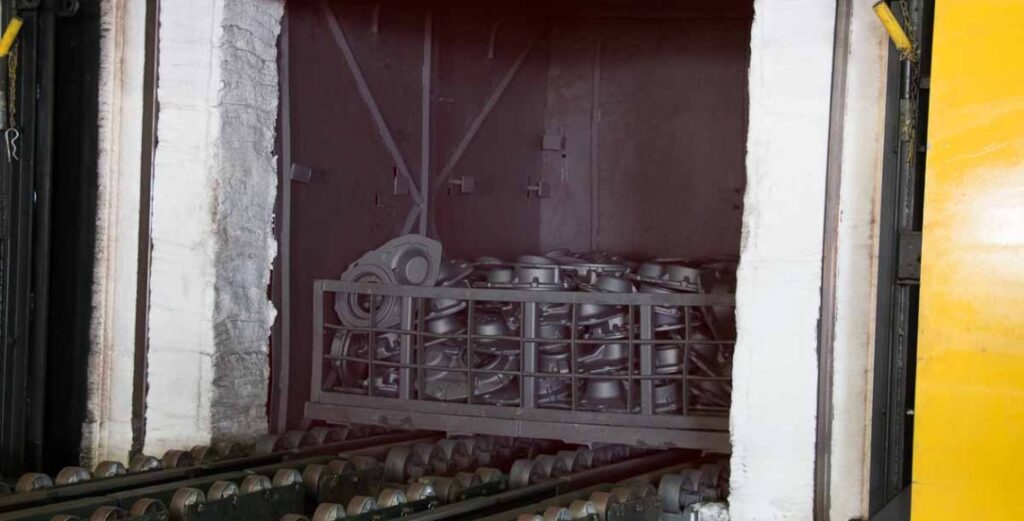

Metals Engineering’s heat treatment capabilities enhance iron and steel alloys ranging from small parts to large-scale load sizes reaching 60,000 pounds at its Green Bay and De Pere, Wisconsin, facilities. The dual plants enable Metals Engineering to offer some of the fastest turnaround times in the heat treatment industry.

“Our computer-controlled heat treatment furnaces and other machinery have the ability to heat and cool materials to specific temperatures and at precise rates,” said Ted Kemen, owner and CEO of Metals Engineering. “We’re able to deliver consistent results for products used in a wide range of industrial applications.”

Thermal stress relief strengthens steel and iron components. Metals Engineering’s stress-relieving steel process reduces the level of residual molecular stress by heating the material uniformly to a suitable temperature, and then slowly cooling it to minimize the development of new stress.

Quench and Tempering

Metals Engineering uses this three-step process to strengthen and harden steel. The first step involves heating to a specific temperature while maintaining a set carbon-controlled atmosphere. The second step is quenching the steel or iron in agitated oil, and the final step involves tempering the parts to a hardness range specified by the customer.

Metals Engineering has six furnaces capable of quenching loads up to 2,000 pounds, complemented by tempering furnaces for completing the process.

Annealing

This term refers to the process of heating, holding and cooling metallic materials. Metals Engineering uses this process to soften steel and iron to improve its machinability while enhancing its dimensional stability.

Annealing can be accomplished in Metals Engineering’s large, car bottom furnaces in an open-fire atmosphere or in smaller nitrogen atmosphere furnaces. Ramp, hold and cooling rates can be programmed to customer specifications, or Metals Engineering specialists will help develop a cycle appropriate to customer needs.

Normalizing

Commonly confused with stress relieving, normalizing is performed at a higher temperature to refine the grain structure and impart hardness to steel or iron.

This process involves heat treating steel to temperatures above its transformational range, and then cooling it in still or fast air.

Metals Engineering has developed normalizing procedures that are effective for parts as small as one pound to castings that weigh more than 6,000 pounds. The company has the expertise necessary to creatively cool parts that meet customer specifications.

About Metals Engineering, Inc.

Metals Engineering is an ISO 9001:2008-certified commercial heat treater with facilities in Green Bay and De Pere, Wisconsin. The company offers a wide range of heat treatment capabilities designed to meet stringent customer requirements. For more information on Metals Engineering’s capabilities or to request a quote, go to https://metalsengineering.com/ or call 920-339-8590.